The main focus of the project IDiD – Implementation of DeD AM in future manufacturing is to promote the use of Direct Energy Deposition (DeD) technology for metal production. DeD is arguably the most suitable Additive Manufacturing (AM) technology for the production of large metal products. As a new technology, the foundation for the adoption of DeD is limited. Despite the large number of metal workshops and relevant production activities in the Nordic Region, metal AM, especially DeD is yet to be effectively utilized. This project will inform the companies from the metal production sector about the product and supply chain impacts of the AM DeD adoption and the possible transition process. IDiD also establishes the foundation for cross-border research, development, and innovation in AM.

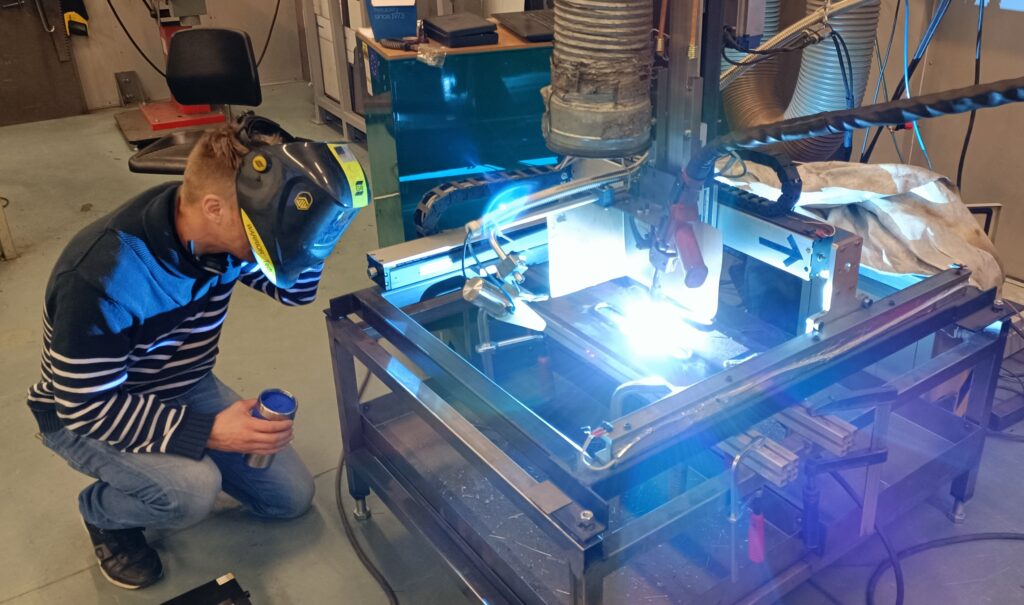

IDiD uses a holistic approach that investigates material properties, design, technological, and supply chain aspects of DeD AM in future manufacturing. Laboratory experiments will be conducted to search for possible breakthroughs in the design and manufacturing of next-generation sustainable products. Literature surveys, conceptual models, and panel discussions with international equipment-and-service providers and experts will be the basis for generating guidelines on the use of DeD in various production lines and use cases. Case studies will investigate financial and non-financial aspects by comparing the costs and benefits of adopting different solutions. Finally, the competitiveness of DeD in Northern Scandinavia will be investigated empirically considering multifaceted aspects from material and technology to supply chain performance.

Overall, IDiD will establish the necessary knowledgebase for the adoption of AM to produce medium and large-sized metal products, which is particularly beneficial for the sustainable development of remote areas.

Contact: Antti Järvenpää, Project Manager, University of Oulu. antti.jarvenpaa@oulu.fi